Aluminium was once described by an aspiring promotional film maker as the second most boring industry in the world, after concrete…still what did Walt Disney ever know about creativity…yes we lack the glamour of the media or premiership football even plastic injection moulding with its exotically high tooling costs and low unit price but as an industry we employ 20k people in the UK and contribute over 3 billion annually to the economy. We make great things, and key to that is the help we can give at the design stage

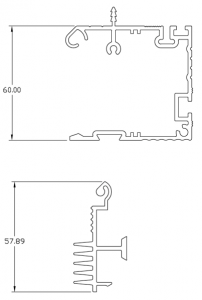

Ideally what is easy for us is easy for you..so follow the simple rules; where possible, uniform wall thickness, symmetry and depth/width ratios of 3-4:1 and few voids. You will see from some of our imagery that we regularly do ratios significantly higher than these but this can come at a cost.

The attached graphic demonstrates many of these features

Linear Threads

For longitudinal fixing

Nut slots

One of the many benefits of extrusion is its capacity to incorporate nut slots of many differing sizes ideal for captive fixing and used extensively in machine build and construction sections

Heat sink fins

One of the most tricky sections to produce, due to the high depth to width ratio, we have a long and successful history in this area as can be seen in some of our imagery. Always ask

Rads

Simply make extrusion easier. It isn’t possible to get sharp corners in the extrusion process so always aim for the max rad you can live with.

Castellations

These are ideal to break up the surface of an extrusion. They can be used to conceal die lines or heat affected areas when extruding hollow sections.

Clip fits

There are many types of clip fit the best being determined by the general sectional geometry. Tell us what you need and we will do our best to comply. A good clip fit is very subjective and its success is driven as much if not more by fit and function as tolerancing

Ball and socket hinges

These tend to be used where access is needed to the end product, such as in a lighting application an electrical trunking profile or an electronic enclosure. Again fit and function is the driver on these as taking into account movement over the length of the end product is key to the success of the fir

Slide fits

Only really recommended over short spans and if anodised

Dovetails

As above

Gasket grooves

We work with one of the premier plastics companies in the country to ensure a good seal wherever possible using an existing plastic section

Fir trees

Used extensively during the 80’s and 90’s in the fitted kitchen and office furniture sectors there is still a place for this type of geometry

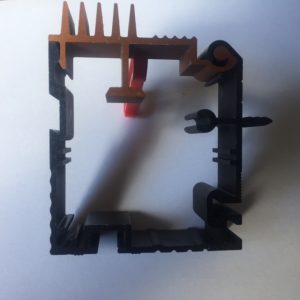

Prototyping

We are developing a prototyping side which will give our customers the opportunity to have one offs made in different materials… Ask for details…